Introduction

In the food industry, packaging is far more than just a container. It plays a vital role in ensuring food safety, enhancing the consumer experience, and communicating your brand's identity. As global regulations tighten and eco-conscious consumers demand greener alternatives, paper-based packaging is gaining popularity for its renewability, recyclability, and excellent printability. This article offers a clear breakdown of the most commonly used types of food-grade paper for packaging, helping you make smarter choices for your business.

Food-grade Packaging Paper Types

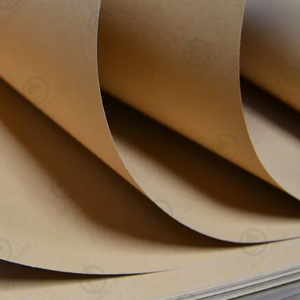

Uncoated/Light Coating Cupstock Base Paper

Uncoated or lightly coated cupstock base paper is a specialty paperboard designed for disposable cups. Made from 100% virgin wood pulp, it ensures food safety and offers a natural feel without any surface coating. It’s strong, has good liquid resistance, and is suitable for direct contact with both hot and cold beverages.

Unlike coated paper, the surface of this paper is naturally porous and matte, giving it a more organic appearance and excellent ink absorbency. This makes it ideal for printing custom logos and branding. The grammage typically ranges from 150gsm to 350gsm, allowing flexibility depending on the final application.

Besides hot and cold drink cups like coffee or soda cups, this uncoated food packaging paper is also used for soup bowls, salad containers, chocolate wrappers, and even dry food or pharmaceutical packaging. Its durability supports handling and transport, while its renewable fiber source and absence of harmful additives make it a sustainable food packaging solution.

When better liquid barrier properties are required, PE coated cupstock paper is the go-to solution. This paperboard is coated with a layer (or two) of polyethylene (PE) on the surface to prevent leaks and resist grease. The base is typically made from virgin wood pulp for added strength and smoothness, ensuring high performance in both structure and printing.

If your packaging is for hot or room temperature drinks, single-sided PE coated paper is usually sufficient. However, for cold drinks, ice cream, or other frozen beverages, double PE coating is recommended to prevent outer condensation or seepage.

This paperboard performs exceptionally well in printing. The coated surface allows for sharp, vibrant brand graphics, making it ideal not only for cups but also for bowls, takeaway containers, and PE coated food trays. It’s widely used in fast-moving consumer goods (FMCG), especially in takeaway and beverage sectors.

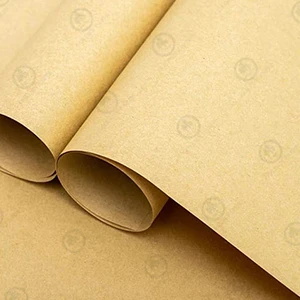

Food Packaging Board with Kraft Back

Kraft back food packaging board features a dual-layer structure—one side is sturdy kraft paper for strength, while the other is a coated white surface for printability. This combination makes it ideal for food containers that need both durability and a high-end appearance.

The kraft side is often made of virgin or a blend of virgin and recycled fibers, balancing strength and sustainability. The white side is coated with a clay or pigment layer that ensures a smooth and printable surface, suitable for high-resolution branding and text.

This kraft backed food board can support heavier food items and offers moderate moisture resistance, making it suitable for takeout boxes, frozen food packaging, and dry goods. In addition, its recyclable nature makes it an environmentally friendly choice for modern packaging needs.

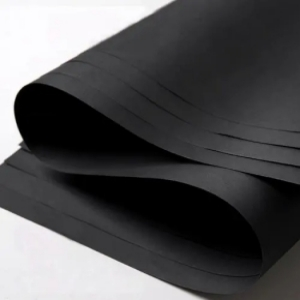

Greaseproof Paper

Greaseproof paper is specially engineered to resist oil and grease, making it a favorite for packaging oily or fried foods such as burgers, fried chicken, fries, and baked goods. Its oil-resistant properties are achieved through two main methods: high-degree beating of pulp (which reduces paper porosity) or surface treatment with oil-resistant coatings.

The pulp used can be bleached, semi-bleached, or unbleached chemical wood pulp. Greaseproof paper combines high oil resistance with decent strength and tear resistance, making it practical for use in high-contact, high-movement packaging.

Its smooth surface also allows for effective printing, making it both functional and visually appealing. In addition to food use, greaseproof wrapping paper is also used for oily industrial components, kitchen liners, and tray liners.

MG Paper (Machine Glazed Paper)

MG paper, or Machine Glazed paper, is distinguished by its unique one-sided glossy finish created through a specialized calendering process. One side is highly polished and smooth, while the other remains more natural and slightly rough, offering a balance of visual appeal and practicality.

Typically made from bleached or semi-bleached pulp, the glossy side is great for branding and printing, while the rougher side is excellent for adhesion or folding. This makes MG paper popular in confectionery, bakery packaging, cosmetic wraps, and pharmaceutical packaging where both functionality and appearance matter.

MG paper is also known for its strength, pressure resistance, and high-quality finish, making it a favorite in luxury food packaging and custom printed gift wraps.

Related keywords: MG paper for packaging, single-side glazed paper, machine glazed food wrap, glossy food wrapping paper

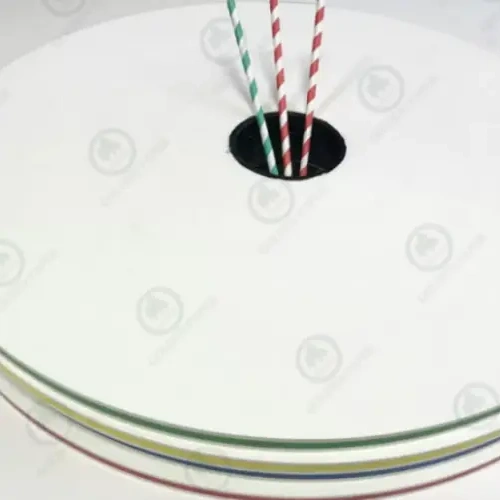

Liquid Packaging Board

Liquid packaging board is a multi-layer paperboard designed specifically for liquid food items like milk, juice, soy milk, and ready-to-drink beverages. It offers excellent stiffness, sealing performance, and moisture barrier properties, thanks to its laminated PE or aluminum foil surface.

The core is made from virgin pulp and layered to create rigidity and leak resistance. The outer layer supports high-resolution printing, making it suitable for colorful branding on products such as milk cartons or juice boxes. It’s compatible with sterilization processes like pasteurization and maintains strength in cold-chain logistics.

Eco-friendly options are available as well, including bio-based PE coatings or aluminum-free structures that enhance recyclability. This makes liquid food paperboard a smart choice for sustainability-conscious beverage brands.

Conclusion

Different types of food require different packaging materials. Choosing the right paper for food packaging not only ensures product safety but also enhances brand visibility and meets sustainability goals. Whether you need uncoated cupstock, PE-coated board, greaseproof wrap, or liquid packaging board, Golden Paper can help you find the right solution tailored to your needs.

GOLDEN PAPER

GOLDEN PAPER

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi  tr

tr  id

id